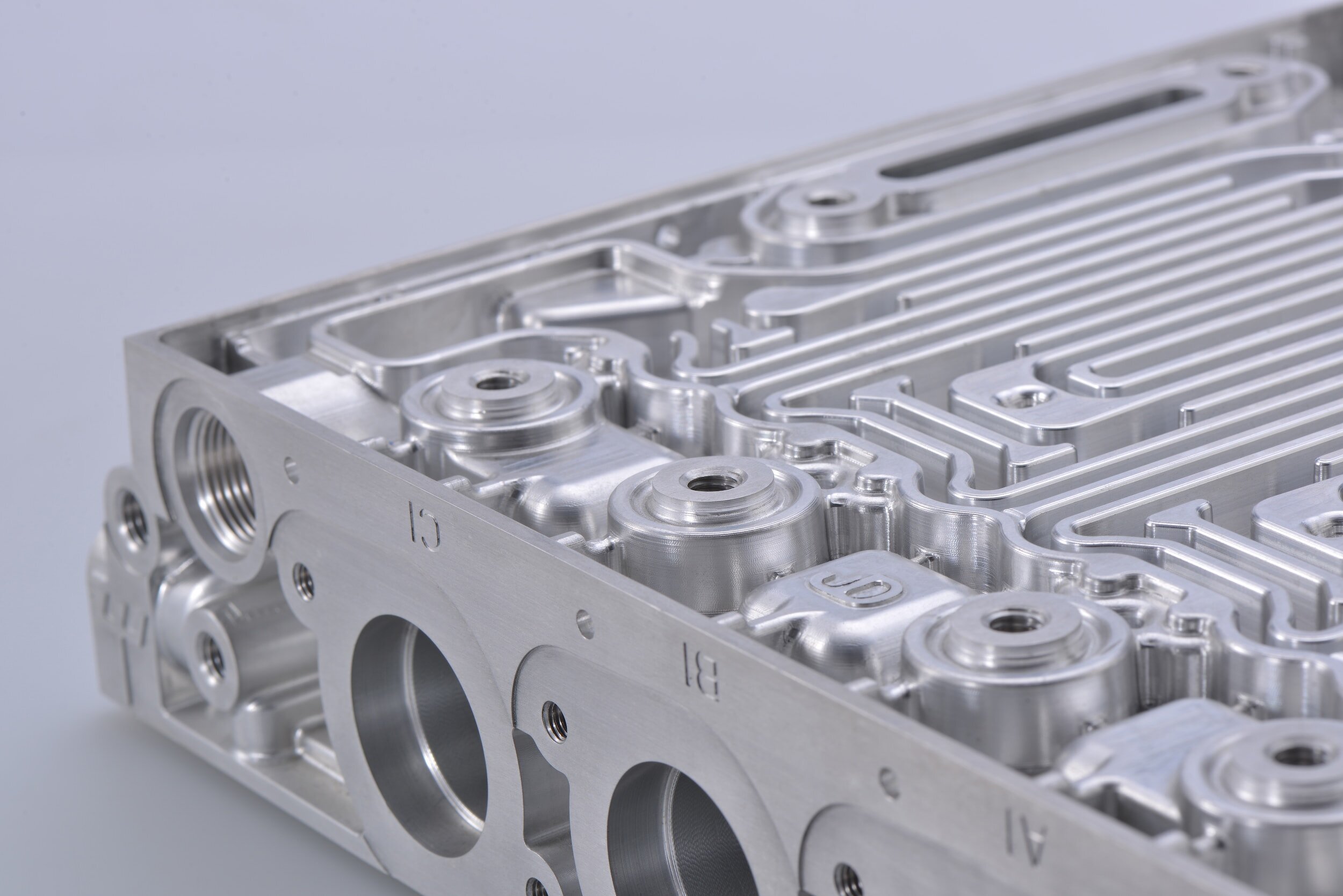

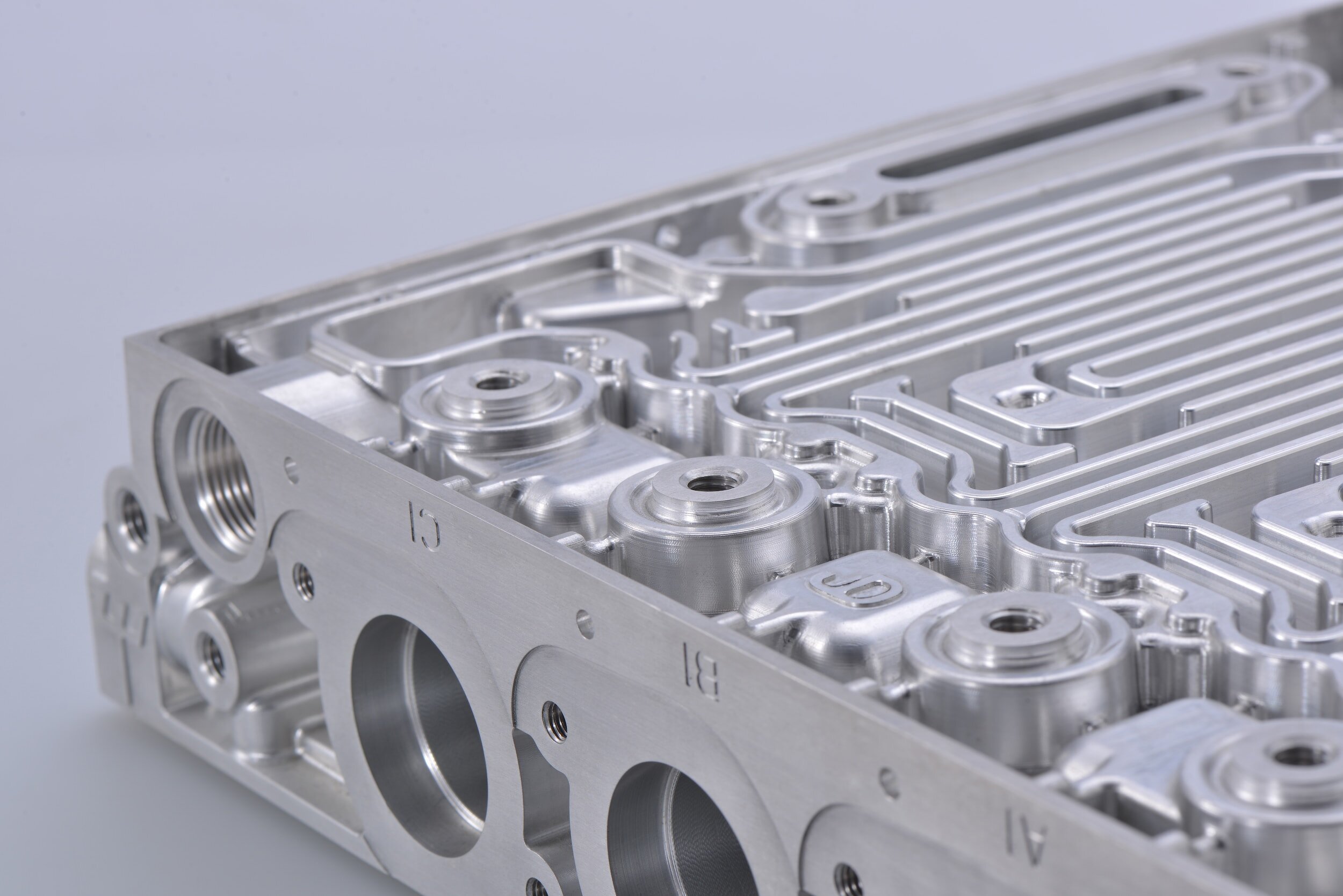

Our Capabilities

With cutting-edge equipment on-site, Ultimate Profiling & Machining guarantees required design and tolerances, while meeting strict project timelines. We also maintain comprehensive records of project specifications, enabling swift fulfilment of repeat maintenance orders.

Pinnacle AX450

5-axis (3+2) CNC mill

Rotary table (X500mm – Y500mm)

24-tool carousel

Hartford Omnis 1020

3-axis CNC mill

Rotary table (X1200mm – Y475mm)

20-tool carousel

4th axis indexing head

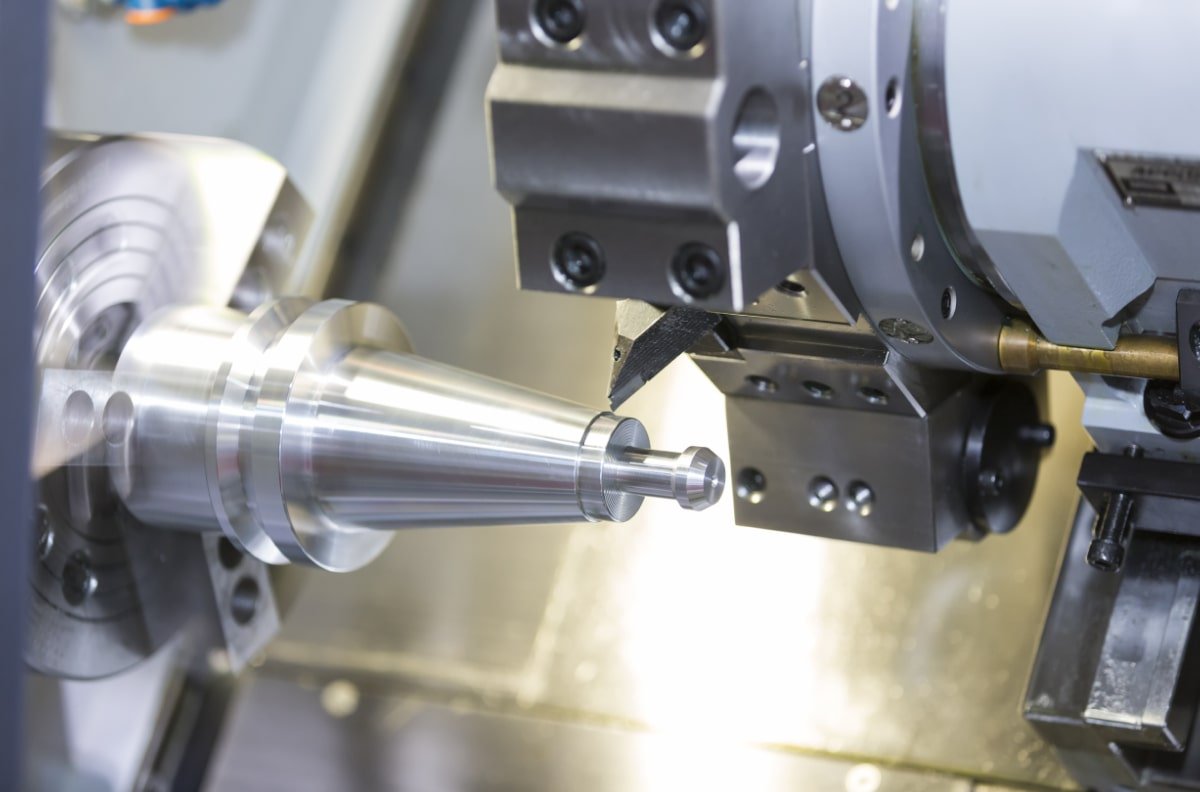

Pinnacle SB520

10” chuck CNC lathe

54mm through spindle coolant

8-station turret

Tailstock

Swift Cut 3000WT Pro

105A plasma table

Software compatible with most file types

Pierce-cut (20mm), Side-cut (40mm)

Table specifications 3.0m (L) x 1.5m (w)

Water table included

Other services offered by UPM

Manual mill and lathe

Automated surface grinding offsite via close relationships with preferred partners.

Band saw and cold saw

50t manual hydraulic press

3m brake press

3m guillotine/sheer

Prototyping

Drafting via UEMS

Reverse engineering via UEMS

Modelling via UEMS

As a proud member of the Ultimate Engineering and Maintenance Services Group, UPM benefits from the extensive support network provided by UEMS. This affiliation enables us to offer a comprehensive range of services, eliminating the need for multiple phone calls.

We prioritise every job with utmost importance, recognising the financial impact of downtime on your business.